Project Overview

- LocationMontpelier, Vermont

- OwnerCity of Montpelier

- EngineerDeWolfe Engineering Associates; Hallam, ICS & Ever-Green Energy, Inc.

- Completed2013

- Contract$4,247,376.60

- Services

Scope:

- Heat Distribution pipe network encompassed 5,050 LF of trenching with dual piping, return & supply lines totaling 10,100 LF.

- Service and Spur lines encompassed 2,292 LF of trenching with dual return & supply lines totaling 4,584 LF of pipeline.

- Total of 19 customers/ 21 buildings serviced by Montpelier District Heat.

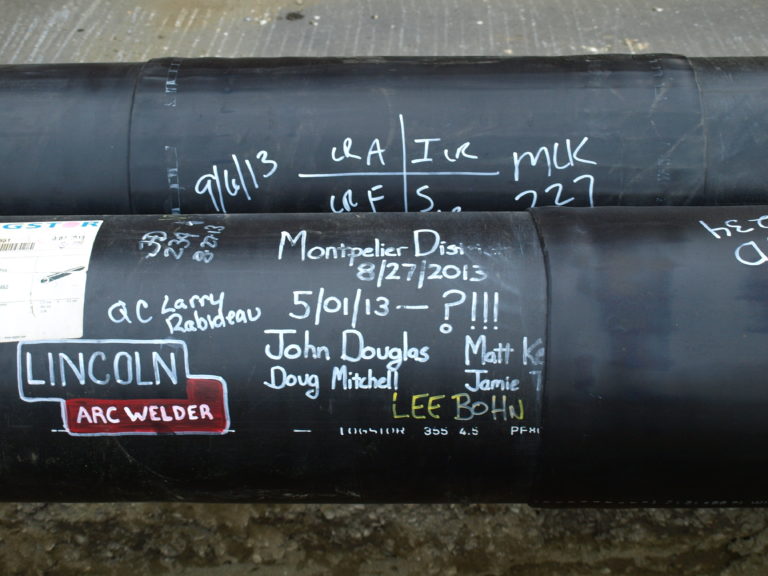

- Total of 930 welded joints with a strict 15 step policy of quality

- The contract also converted two public buildings to district heating water, the Montpelier City Hall and the Police Station.

- Installed 11 Drain Assemblies, so called ‘Flash Chambers’ as they are required to with stand hot water at 220 ̊F and a total of 22 air release assemblies at high points in the system.

Meeting the challenge of a difficult job.

The Montpelier District Heat Project includes over 10,000 LF of welded, thin wall steel pipe installed through the downtown streets. The nature of the specialty pipe utilized, combined with the unknowns of centuries old streets, resulted in simple layout changes requiring redesign for any rerouting that was required. Unforeseen conditions such as old foundations, contaminated soils, unknown and aging utilities all contributed to the difficulty of the installation. The total number of services was not established at the beginning of the project and coordination with local businesses connecting to the system with different operating hours and constraints required a juggling act of crews. Once inside the establishments, the old buildings presented as many unknowns as the city streets. Tight streets with limited parking and a requirement to keep all storefronts fully functional while also accommodating special social events all factored in to the project complexity. Unusually wet weather at the start of the project, delays in obtaining easements and delays in final design of connections to the State Heating Plant all added to the challenge.

Excellence in project management.

The project required the management team to anticipate, coordinate and expedite delivery of materials manufactured exclusively in Europe. Consideration for long lead times and interfaces between metric and imperial pipe, appurtenances and fittings required diligence to avoid delays. The management team scoured the plans for inconsistencies and potential problems and notified the Owner/Engineer for clarification long before the work required it. Many questions resulted in redesigns and a revised list of materials needed. The complexities and unforeseen conditions required daily reallocations of resources to other areas of the work. The team worked tirelessly to provide the best available schedule information for public notification. And, finally, the team maintained a good natured and positive attitude regardless of the obstacles met and schedule change requests made.

Innovation in construction techniques, materials or scheduling.

The Logstor pipe incorporates a number of innovative techniques for installing hot water lines including integrated insulation, waterproof covering, shrink wrap joint covers, dual wire leak detection system and dedicated fiber optic monitoring system. Installation requires a multistep Quality Control reporting system to assure that each step has been satisfactorily completed. All of Kingsbury Companies’ installers were factory certified to complete their respective tasks. Because of the time required for each joint, many of the components were constructed off-site and threaded through the existing utilities to shorten the on-site construction time. This was a necessity to ensure the daily reopening of roads and parking.

Excellence in client services.

In order to complete the project in one season, 3 pipe crews were required within the city center creating considerable disruption to normal traffic flow. Throughout the project, pedestrian access was provided to all of the City storefronts and countless accommodations were made for replacement parking, special events, parades, farmers market and other planned and unplanned City events. The construction team worked very closely with City management to minimize impacts of this substantial project.

Project’s contribution to the community.

The ambitious District Heat Project will provide generations of beneficial utility in delivering hot water to federal, state and city buildings, as well as, businesses and residences from a renewable, locally provided fuel source.